A Unique Perspective on Springs

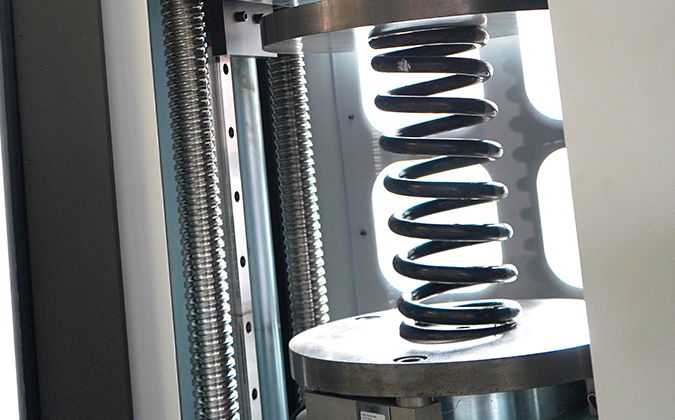

We have been working with, testing, analysing and helping to design springs for decades. Our experience, knowledge, and dedication to spring health and safety give us a unique perspective when investigating spring failures – allowing us to determine the route cause of failure and recommend how to eliminate the risk of future failures, which no other service can offer.

Minimise the Risk

Springs are critical components in an enormous number of products and control systems used worldwide. A spring failure in-service is at best considered unacceptable and at worst catastrophic. We believe it is essential to understand how and why a spring failed to minimise the risk of future failures.

Minimise the Risk

Springs are critical components in an enormous number of products and control systems used worldwide. A spring failure in-service is at best considered unacceptable and at worst catastrophic. We believe it is essential to understand how and why a spring failed to minimise the risk of future failures.

Why Choose Us?

We have a broad, in-depth knowledge of springs and robust failure analysis procedures. Over the last couple of years, we performed failure analysis on wave springs used in oil and gas valves, nested springs in train bogies, commercial vehicle leaf springs, engine valve springs, medical auto-injector springs and Tuk Tuk suspension springs.

What’s in a Failure Analysis?

Our failure analysis procedure includes; visual, microstructural, and SEM imaging and examination, hardness tests and EDX analysis. Combine this with the expert spring knowledge of our metallurgists, and we will write a detailed report including our findings, annotated images and recommendations as standard.

What’s in a Failure Analysis?

Our failure analysis procedure includes; visual, microstructural, and SEM imaging and examination, hardness tests and EDX analysis. Combine this with the expert spring knowledge of our metallurgists, and we will write a detailed report including our findings, annotated images and recommendations as standard.

Failure Analysis Reads