Why Fatigue Test With Us?

As an impartial testing facility, we can independently verify a springs performance. You may use us to:

- Validate a production drawing or operational lengths

- Prove your product is fit for purpose before it goes to market

- Conduct comparative testing for different spring suppliers

- Ensure the supply chain is producing springs of consistent performance and material

Our Testing Capabilities

We are capable of testing the smallest of deflections from 0.30mm up to 250mm and loads to a maximum of 35,000 N. We can also:

- Test cycle rates of 50 Hz / 3000 rpm (speed will vary depending on spring design)

- Load test before and after

- Test torsion, spiral and clock spring types, as well as the more common compression and extension springs

- Test to ten million cycles in as little as three days

Our Testing Capabilities

We are capable of testing the smallest of deflections from 0.30mm up to 250mm and loads to a maximum of 35,000 N. We can also:

- Test cycle rates of 50 Hz / 3000 rpm (speed will vary depending on spring design)

- Load test before and after

- Test torsion, spiral and clock spring types, as well as the more common compression and extension springs

- Test to ten million cycles in as little as three days

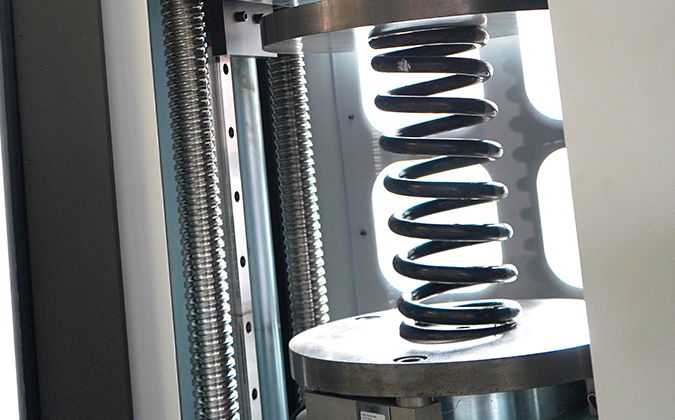

What is Fatigue Testing?

Fatigue testing is a method of working a spring to its expected life using pre-determined parameters. Replicating real-world conditions tells us if a spring is fit for purpose and is the only way to validate a springs behaviour or material.

We work with a wide range of industries, including medical, aerospace, automotive, rail and oil and gas. Whether your spring is designed for single-use or millions of cycles we can help you achieve the performance you expect.

Fatigue Test With the Spring Experts

Use us to independently verify how long your springs will last in service

Ensure your springs are of consistent performance from batch to batch

We can take on custom testing work designed specifically to your spring